Restoration and Lining of Ball Mills

Mills of the MShTs type are designed for grinding ore to sizes suitable for the subsequent separation of valuable minerals from waste rock. The mill body, known as the "drum," along with the end walls, is protected by standard thick armor plates that provide resistance to impact and dynamic loads.

However, these armor plates do not provide protection against erosion caused by washing, cavitation, corrosion, and abrasive wear due to the impact of fine particles. Constant operation creates difficulties in timely inspection and assessment of the wear degree of mill components, necessitating planned preventive maintenance and repair.

Weartech Forte Mill Body Strengthening System (Poland)

The reinforcement system was developed by the technical team at "Weartech" and is designed for the structural strengthening of metal structures. This system includes components with high tensile and stretch strength. Additionally, due to its high degree of adhesion, the system can operate continuously with a stable structure and prevents the possibility of delamination of the reinforcement components from the reinforced element.

The updated design strength of the Weartech Forte reinforcement system uses carbon fiber with high-strength unidirectional fiber and a tensile strength of at least 4850 N/mm² and can withstand a load of at least 230,000 N/mm².

In laboratory conditions, tested samples of two-layer Ne10 (see 3nc) were compared with the same samples using carbon fiber reinforcement, having a dry coating thickness of 0.333 mm and a weight of 600 g/cm³.

The maximum calculated load is 76 kN. When testing with a load of 75 kN, the non-reinforced beam showed a maximum deflection of 8.21 mm (standard beam - 8.33 mm). Meanwhile, with the same load of 75 kN, the carbon fiber reinforced beam showed a deflection of 3.97 mm.

The reinforcement system includes the following components:

- High-adhesion primer for supporting systems;

- High-strength mastic for protecting carbon fiber in two layers;

- Medium viscosity epoxy adhesive for bonding carbon fiber to enhance the Weartech Forte system;

- Application of carbon fiber with epoxy adhesive to increase strength and integrate the system;

- Final reinforcement of the system with high-strength mastic to protect the fiber.

Completed Metal Structure Reinforcement Projects

- Metal structure reinforcement projects include:

- Development of chemical and technical productions. Enterprises of OAO "AZHKZ", PAO "GKhOKOKS";

- Reinforcement of OK duct components, OAO LITOK;

- Reinforcement of bridge intersections in the cities of Nizhny, Chernushka, Uzlovaya, and others;

- Reinforcement and chemical protection of ammonia-sulfate production metal structures. Zaporizhzhya HZ.

- Other projects.

Before

After

Ultra Ceramik Lining System

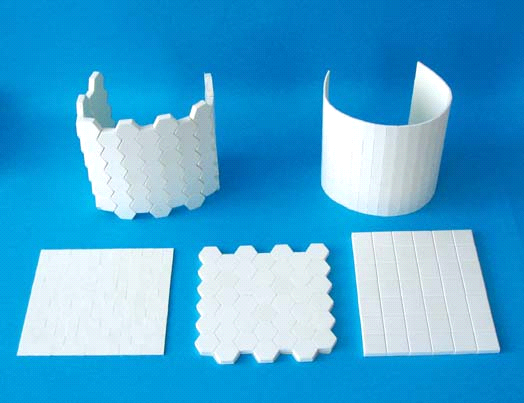

The Ultra Ceramik lining system consists of zirconia and alumina oxide-based tiles measuring 20x20 mm and 4 mm thick. The small dimensions effectively distribute dynamic and impact loads across the lining surface, reducing the risk of system damage. Zirconia-based lining offers excellent resistance to high abrasive loads as well as corrosion and chemical exposure. The tiles are attached using a special thixotropic adhesive mixture with high adhesion to polymers, ensuring a monolithic lining coating.

Ultra Mix SVS Lining System

The Ultra Mix SVS copolymer lining provides resistance to intense impact and vibration loads due to the plasticity and damping properties of the coating. The system includes a special attachment scheme, featuring high-adhesion adhesives for bonding polymers to metal, as well as reinforcement and mechanical fastening with metal elements such as bolts and armor. Multicomponent casting allows for the creation of 3D molecular structures, making the material resistant to high mechanical loads.

Advantages of the Proposed Reinforcement and Lining System

- Ability to perform repair work in the shortest possible time without fire. This saves costs and downtime for equipment.

- Strengthening and protection of the body with an extended service life compared to conventional repair technologies. Unlike standard repair techniques, the proposed method not only restores load-bearing capacity but also increases the remaining wall thickness while maintaining high resistance to repeated wear.

- Ease of work execution. All application processes are done manually with detailed technological instructions, allowing the work to be carried out by regular personnel without the need for additional training.