Cement industry

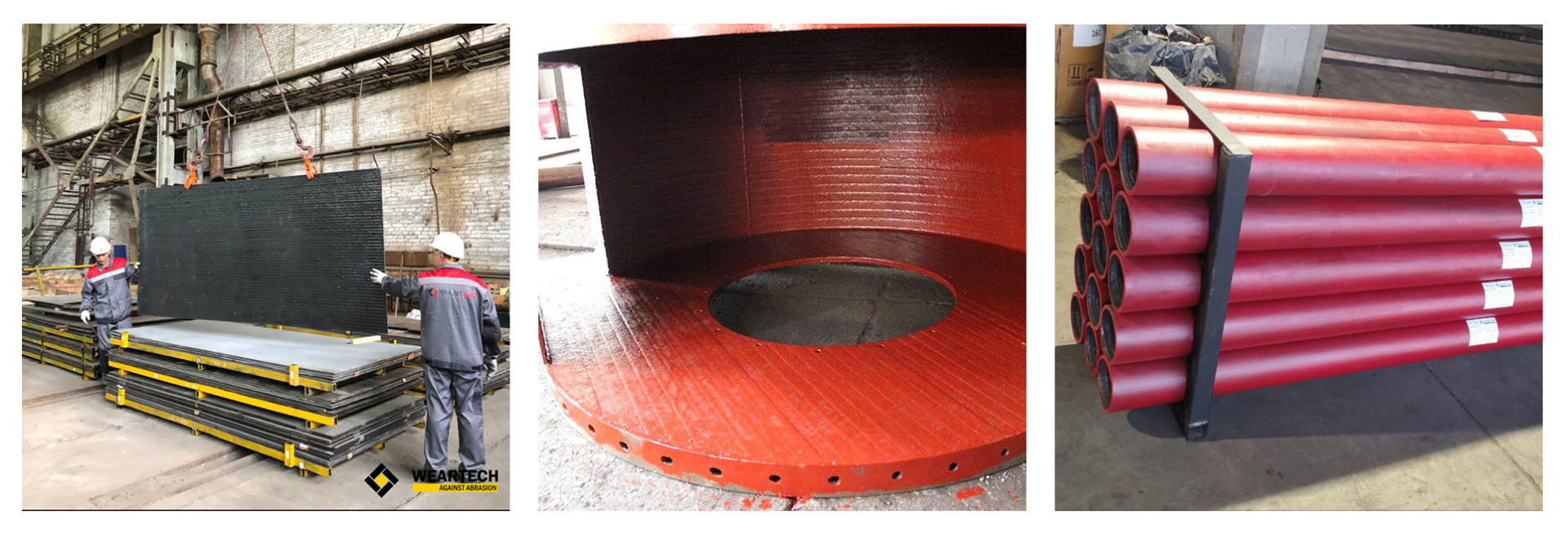

In the cement industry, various types of wear can pose a threat to process equipment. Each type of wear creates unique challenges and requires specific strategies for effective equipment protection. Using appropriate wear-resistant materials, coatings, or lining systems can help mitigate these wear risks and extend the service life of equipment at a cement plant. Among the main types of wear-resistant materials commonly used in the cement industry to protect production equipment from wear are:

1. Bimetal. Bimetal is commonly used in the cement industry to protect equipment exposed to abrasive materials such as limestone, sand, and other aggregates. Examples of bimetal use in the cement industry include:

- Mills. The grinding process in cement production involves crushing and grinding raw materials such as limestone and clay into a fine powder. This process is extremely abrasive and can cause significant wear on mill components. Bimetal can be used to protect mill components such as grinding rollers and grinding tables from wear and abrasion.

- Kiln components. The kiln is a critical component in cement production, where raw materials are heated to high temperatures to produce clinker. Individual kiln parts such as the inlet chamber, burner pipe, and kiln tire are exposed to high temperatures and abrasion. Bimetal can be used to protect these components from wear and extend their service life.

- Conveyor systems. Conveyor systems are used to transport raw materials and finished products throughout the cement production process. Conveyor components such as conveyor belts and rollers are exposed to abrasive materials and can wear out quickly. Bimetal can be used to protect these components from wear and extend their service life.

- Fans. Fans are used in cement plants to move air and gas through the system. The high speeds and abrasive nature of particles in the air and gas stream can cause wear and damage to fan blades and housings. Bimetal lining can be used to effectively protect against wear and extend the service life of fan blades and housings.

- Cyclones. Cyclones are used to separate fine particles from exhaust gases in the cement production process. Cyclone components such as the inner lining and inlet cone are exposed to high speeds and abrasive particles. Bimetal is suitable for protecting these components from wear.

2. Cast basalt. Cast basalt is another technology used in the cement industry to protect equipment by applying cast basalt linings to surfaces exposed to abrasive and corrosive materials. Cast basalt lining can be used in cement plants to protect equipment from wear and abrasion, enhancing equipment durability and reducing downtime for maintenance and repairs. Here are some examples of areas where cast basalt lining can be used in a cement plant:

- Raw material handling area. Cement plants typically process large quantities of raw materials such as limestone, clay, and sand. These materials can be highly abrasive and cause wear and damage to equipment. Cast basalt lining can be used in hoppers, chutes, and conveyors to protect against wear and extend equipment life.

- Kilns. Kilns are used in cement plants to heat raw materials to high temperatures, causing chemical reactions that produce clinker. The high temperatures and abrasive nature of clinker can cause wear and damage to kiln walls. Cast basalt lining can be used to protect against wear and extend the life of kiln walls.

- Cyclones. Cyclones are used in cement plants to separate dust and other particles from the gas stream. The high speed and abrasive nature of particles can cause wear and damage to cyclone walls. Cast basalt lining can be used to protect against wear and extend the life of cyclone walls.

- Silos. Cement plants often use silos to store and transport finished products. The abrasive nature of cement powder can cause wear and damage to silo walls. Cast basalt lining can be used to protect against wear and extend the life of silo walls.

3. Oxide ceramics. High-alumina ceramics, known for their exceptional wear resistance, are widely used in the cement industry to protect equipment from abrasion and impact. Oxide ceramics provide superior resistance to abrasive materials and can significantly extend the service life of protected equipment. Here are just a few examples of cement plant equipment and components that can be effectively protected with oxide ceramics:

- Chutes and hoppers. Chutes and hoppers in cement plants handle abrasive materials such as limestone, clay, and clinker. High-alumina ceramics can be used to line chutes and hoppers to protect them from erosive and abrasive effects of materials, extending their service life.

- Cyclones and separators. Cyclones and separators are crucial components in cement plants for separating fine particles from gases or materials. High-alumina ceramics can be used to line the inner surfaces of cyclones and separators, providing superior wear resistance to abrasive particles, enhancing efficiency, and extending the equipment's service life.

- Milling equipment. Mills, including ball mills and vertical roller mills, are commonly used in cement production for grinding raw materials and clinker. High-alumina ceramics can be used as wear-resistant linings inside the mills, protecting them from abrasive effects of processed materials and reducing maintenance and downtime.

- Kiln components. Cement kilns operate at high temperatures and are exposed to chemical reactions and abrasive materials. Oxide ceramics can be used as refractory linings in kiln components such as the kiln inlet, riser duct, and tertiary air duct. This material provides excellent thermal insulation and resistance to chemical attack and erosion, extending the life of kiln components.

- Wear plates and linings. Various cement plant equipment such as crushers, conveyors, and bucket elevators can benefit from using oxide ceramics as wear plates and linings. These components are subjected to continuous wear and impact, and the application of high-alumina ceramics helps protect them from abrasion and extend their service life.

All these technologies are valued for their ability to enhance wear resistance and durability of process equipment in the cement industry. The choice of material or their combination depends on factors such as specific application, type of wear, operating conditions, and cost-effectiveness. It is important to carefully assess the requirements and consult with specialists from WEARTECH SP to determine the most suitable wear-resistant material for each specific application to protect equipment.

Specialists from WEARTECH SP, based on an audit and analysis of the technological process of a specific enterprise, can develop highly effective custom solutions and designs to optimize the protection of various equipment and components from wear using one of the aforementioned materials or their combinations throughout the production process.