Results of metallographic studies of bimetallic plates

Below are the results of metallographic studies evaluating the microstructure of the welded layer with varying Cr and C content:

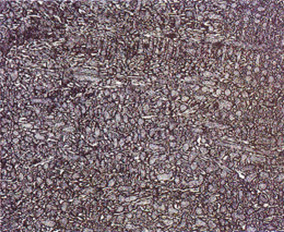

Sample No. 1 – Chromium content – 16.70%, carbon – 2.88%

- C2.88%

- Cr16.70%

- Mn2.03%

- B0.5%

The alloy does not contain visible chromium carbides; most of the chromium content is seen in the matrix as white spots.

Rockwell hardness 51.37 HRC

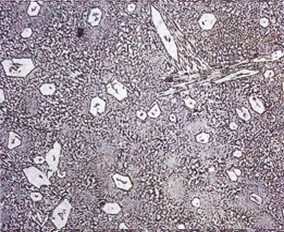

Sample No. 2 – Chromium content – 26.40%, carbon – 3.88%

- C3.88%

- Cr26.40%

- Mn2.55%

- B0.5%

Increasing chromium and carbon leads to the formation of primary chromium carbides, visible as light hexagonal shapes.

Rockwell hardness 55.8 HRC

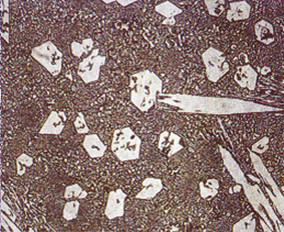

Sample No. 3 – Chromium content – 29.20%, carbon – 4.33%

- C4.33%

- Cr29.20%

- Mn3.22%

- B0.5%

Increasing chromium and carbon leads to the formation of primary chromium carbides, visible as light hexagonal shapes. Rockwell hardness 57.6 HRC

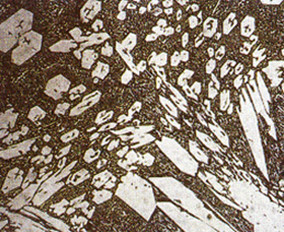

Sample No. 4 – Chromium content – 32.60%, carbon – 4.84%

- C4.84%

- Cr32.60%

- Mn3.34%

- B0.5%

Increasing chromium and carbon leads to the formation of primary chromium carbides, visible as light hexagonal shapes. Rockwell hardness 57.8 HRC

Metallographic studies evaluating the microstructure of the welded layer of 4 different samples with varying chromium and carbon content showed the following results:

- The level of wear resistance of the materials is significantly influenced by the morphology of carbide inclusions, their crystalline structure, size, quantitative ratio, and distribution characteristics within the matrix, despite the high level of hardness.

- Evaluating performance characteristics solely by Rockwell hardness criteria, without considering the structure, will not provide an objective assessment of the wear resistance of the welded layer.

- The strengthening effect is maximally reflected when the chromium content is increased to at least 30% and carbon to more than 4%. This composition has maximum wear resistance.

Thus, with a chromium content of more than 30% and carbon content of more than 4%, the welded layer exhibits the best performance characteristics when exposed to abrasive particles.

Weartech wear-resistant bimetallic plates contain 32-37% chromium and 4.5-5% carbon, with uniformly distributed and strictly oriented high-strength carbides in a ductile austenitic matrix, achieving the highest wear resistance of the protected surface.

Our goal is to create the best wear protection solutions.