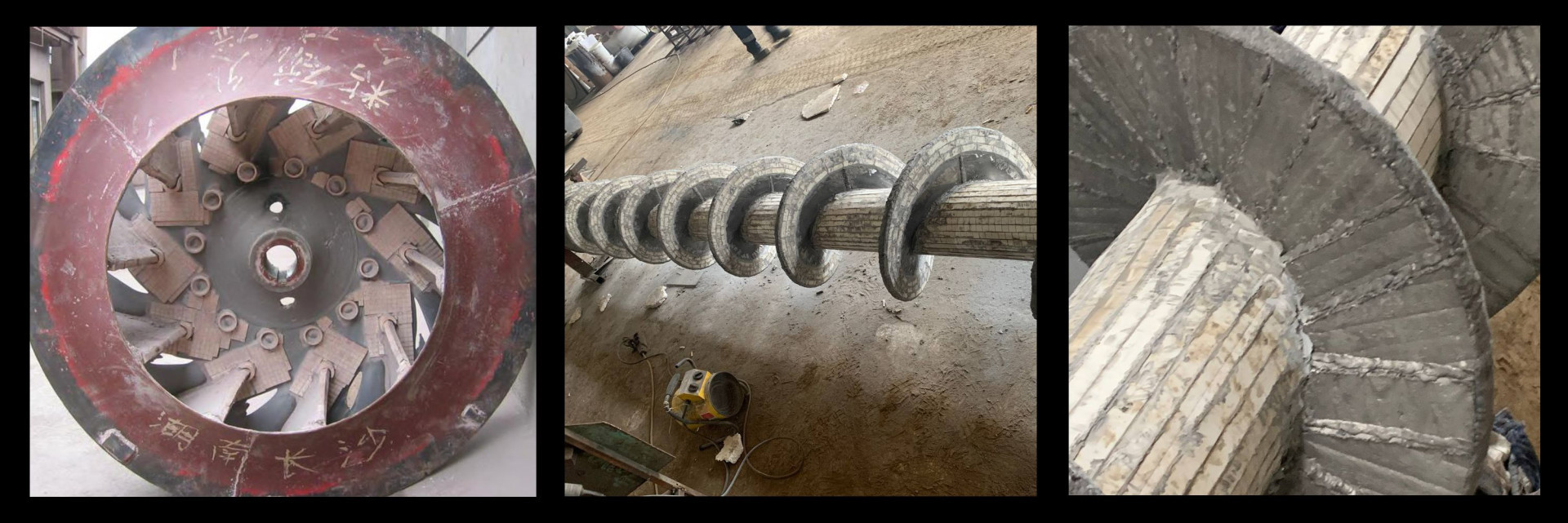

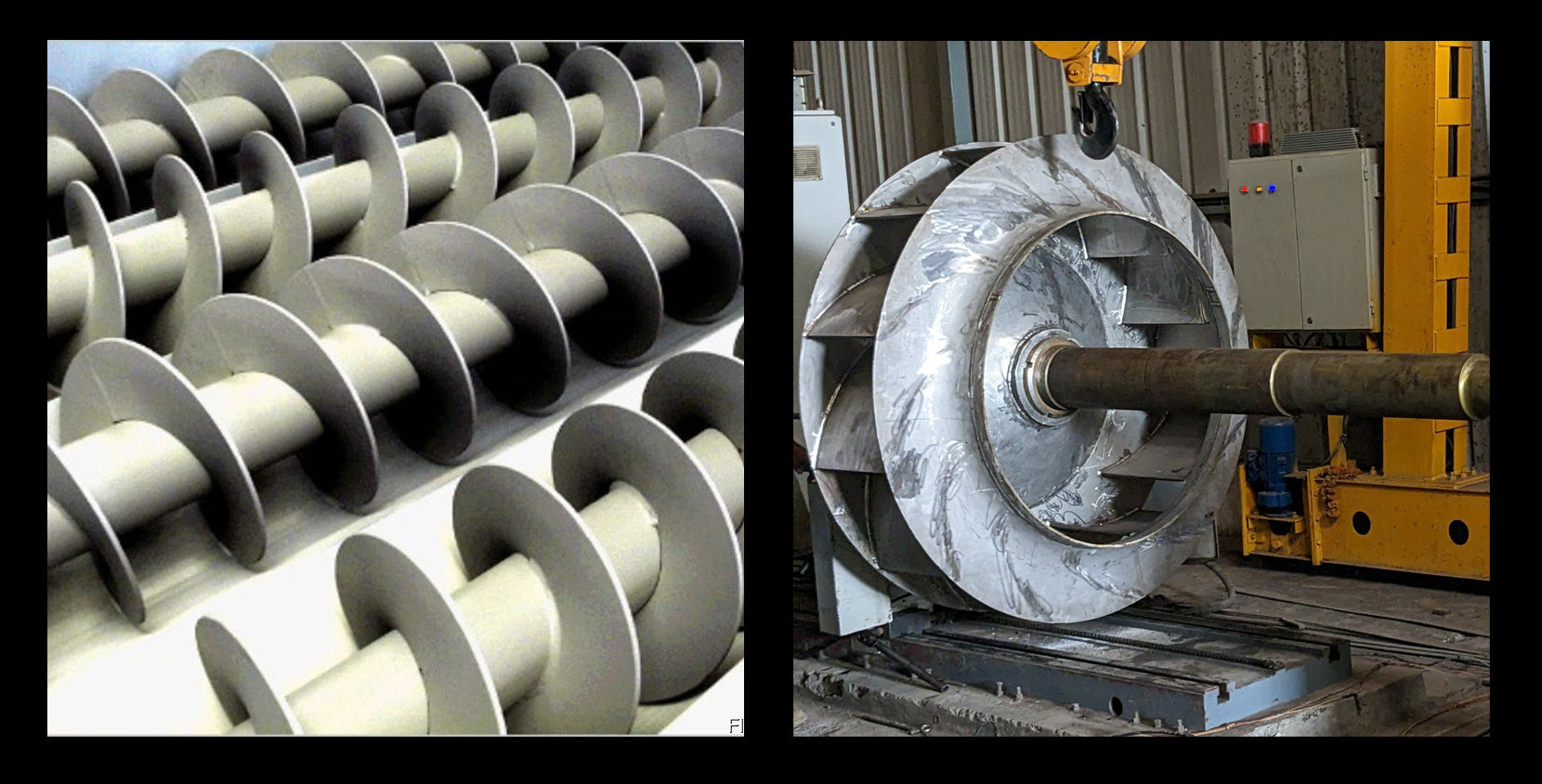

Lining of screws and blades of mill fans

Ensuring Protection of mill fan screws, mill fan blades, blades and housings of exhaust fans, as well as other equipment at power plants from wear through various lining methods is essential for their prolonged and efficient operation. The choice of lining material should take into account the unique operating conditions of the equipment, including the type and characteristics of abrasive elements, temperature regimes, chemical context, and mechanical impacts.

Materials such as ceramics, basalt, carbides, and metals provide excellent protection in the most severe conditions, ensuring resistance to abrasive wear and high temperatures. Polymer compounds, on the other hand, are ideal for less extreme conditions, providing flexibility and reduced costs while offering effective protection against wear and corrosion.

Leveraging extensive practical experience, Weartech offers its clients integrated protection for mill fan blades, blades and housings of exhaust fans, screws, and other equipment through the Ultra Ceramik-C system, based on elastomeric polymer adhesives and plates made of zirconium and aluminum oxides. In terms of wear resistance, this lining method is seven times more effective than electrode hardfacing.

Implementing effective wear protection techniques involves thoughtful design and consideration of all operational aspects. Investing in high-quality lining and conducting systematic maintenance can significantly reduce operating costs while increasing the efficiency and safety of production processes at power facilities. Proper selection and application of wear-resistant lining materials contribute to maximizing the service life of equipment, ensuring its stable and high-performance operation for many years.